Andrew Birnie, Systems Engineering Manager for Automotive Microcontrollers and Processors. This week saw the publishing of the shocking United Nations report on the transformation of Earth’s natural resources and landscapes by humans. It is a timely reminder for us at NXP why we are pushing so hard to move forward on more sustainable measures for transportation. Even without the added impetus of social responsibility, rapid innovation in automotive means that developing solutions capable of responding to the requirements of new sustainable vehicles is necessary.

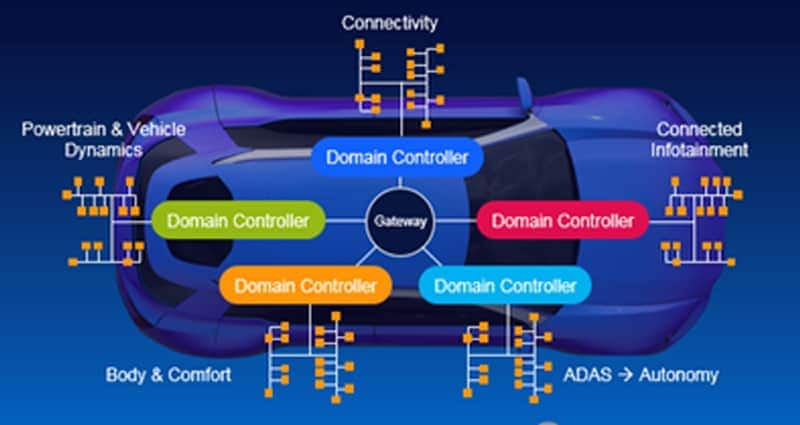

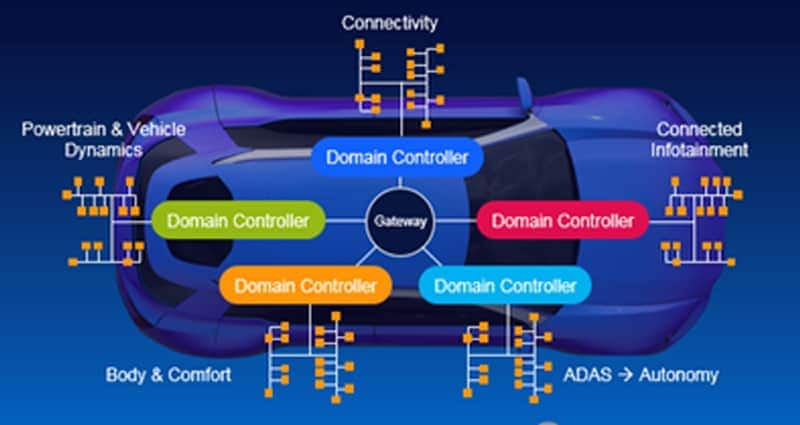

One way of being able to deal more efficiently with these innovations is through evolving electrical architecture to one of domain control. This means that each functional area can be split into its own collaborating sub-network, with a domain controller acting as an access point from the vehicle. Domain control is a philosophy, not an ECU. Each controller in the hierarchy combines to implement the functionality of the domain, and each controller can make appropriate decisions for the purpose of the domain. Previously there was one ECU per function, with low data exchange between them. But domain architecture provides a more holistic efficient system level approach, with reduced ECU count and reduced overall wiring.

In electrification, the propulsion domain a high-performance node that delivers computational and mathematics performance. Predictive model control techniques can be used to improve instantaneous efficiency of ICE or electric motor using Kalman filtering or state space modeling. Torque decision making can be improved by using an array of vehicle data combined with crowd sourced data of other road users. That data can be utilized in mathematically intense control strategies, using machine learning techniques, to realize a significant increase in vehicle efficiency and therefore range. Studies have shown that as you grant more predictive control to the domain controller, efficiency savings of up to 30% are possible.

To deliver on this functionality and performance, many MCU suppliers have been instantiating 6, 8, 10 cores and more. However, this approach can cause software architecture challenges due to the difficulty of parallelizing the system.

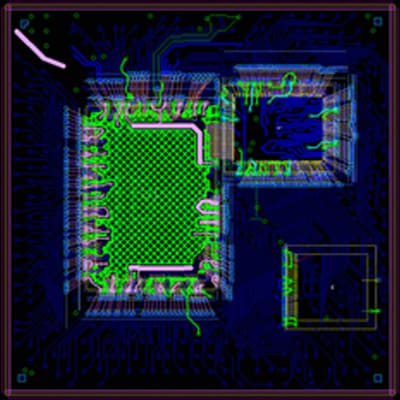

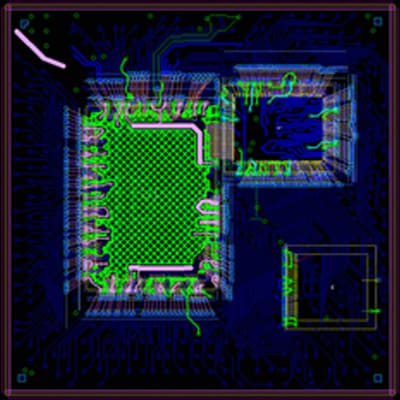

At NXP, we have struck a new path by splitting the MCU into its constituent functions and implementing an optimum process technology for each. The separate die with high-frequency interfaces are then combined into a system-in-package. From the outside, the 3-die are invisible—they look, behave and operate exactly like a traditional MCU, but with the full performance of the base CMOS process.

Moving beyond the advantage of this SIP concept for energy optimization within the propulsion controller, ECU consolidation cannot happen efficiently without virtualization techniques like a hypervisor. Here, tasks can be separated within an MCU into virtual machines (VMs), giving a method to assign and reserve resources to each task. This helps guarantee freedom of interference, which is essential within these consolidated ECUs where the majority of the tasks are safety critical.

For electrification, where safe and energy efficient management of the torque sources are needed, new microcontroller approaches are needed to deliver the real-time performance, safety, security and virtualization in the MCU needed to make it possible. This type of MCU requires innovative approaches.