Over the past year, a series of IoT-themed senior design projects by

students at Texas State University were created based on

Kinetis microcontrollers

and

Thread wireless networking technology. One of the projects was a remote weather

station that measures temperature, barometric pressure, wind speed,

wind direction and rainfall and transmits the data over a Thread network.

This is a great IoT application example that uses multiple sensors

– each with very different functional, timing and signal

characteristics – and can be easily implemented using a single

Kinetis microcontroller that has wireless connectivity.

Thread-connected remote weather station built by Texas State University

students

Key components of the weather station

The weather

station is designed around a

TWR-KW24D512

Kinetis Tower System module, which provides the necessary microcontroller

functionality for the sensors and wireless connectivity for the Thread

networking protocol. The anemometer (wind speed), weather vane (wind

direction) and rain gauge sensor functions are implemented using a SparkFun

SEN 08942 Weather Meter kit. A TWRPI-MPL115A2 barometer attached to the

TWR-KW24 board is used to measure atmospheric pressure. A Texas Instruments

TMP36 analog temperature sensor is used to measure ambient temperature. A

TWR-PROTO

board together with a

TWR-ELEV

system provides space for additional circuitry and robust connections to the

external sensors.

The electronic components (excluding most of the sensors) are contained in a

weatherproof enclosure mounted to the base of the weather station mast. The

entire station is powered from a USB adapter plugged into a 110V AC outlet in

the enclosure. The sensors are all connected via modular RJ11 jacks.

TWR-KW24D512 Tower System and wiring in the weatherproof enclosure

TWR-KW24 Configuration

Together with the integrated low power 2.4 GHz IEEE 802.15.4-2011 radio

frequency transceiver, the

MKW24D512

device includes:

- 50 MHz Arm Cortex-M4 Core (1.25 MIPS/MHz)

- 512 kB of flash and 64 kB of RAM

- Power management controller with 10 different power modes

-

Security features including, secure flash, tamper detect, cryptography

acceleration unit and 128-bit random number generator

-

16-bit SAR ADC with one differential and up to 11 single-ended external

analog inputs

-

Various timer modules including FlexTimer, Periodic Interrupt Timer,

Programmable Delay Block and Independent Real –Time clock

- USB, SPI, UART and I2C interfaces

- Up to 28 GPIO channels

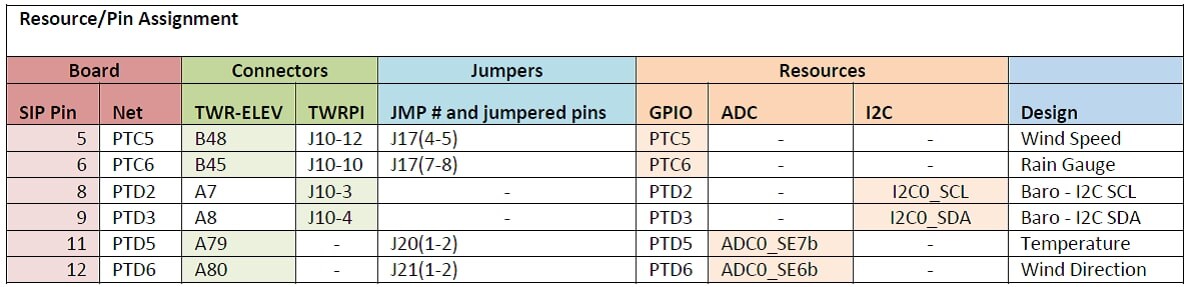

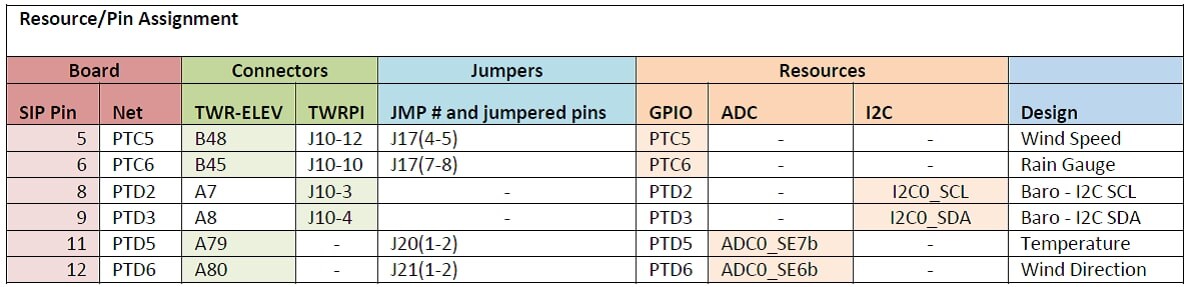

The sensors used for the weather station project use two ADC channels for the

wind vane and temperature sensor, two GPIO channels for the wind speed and

rain gauge and an I2C channel via the TWRPI connector for the barometric

pressure sensor.

TWR-KW24 resource assignment, board connection and jumper configurations

Sensor algorithms

The sensors each have very different

functional, timing and signal characteristics, so one of the challenges of

this project was developing appropriate interfaces and algorithms for each of

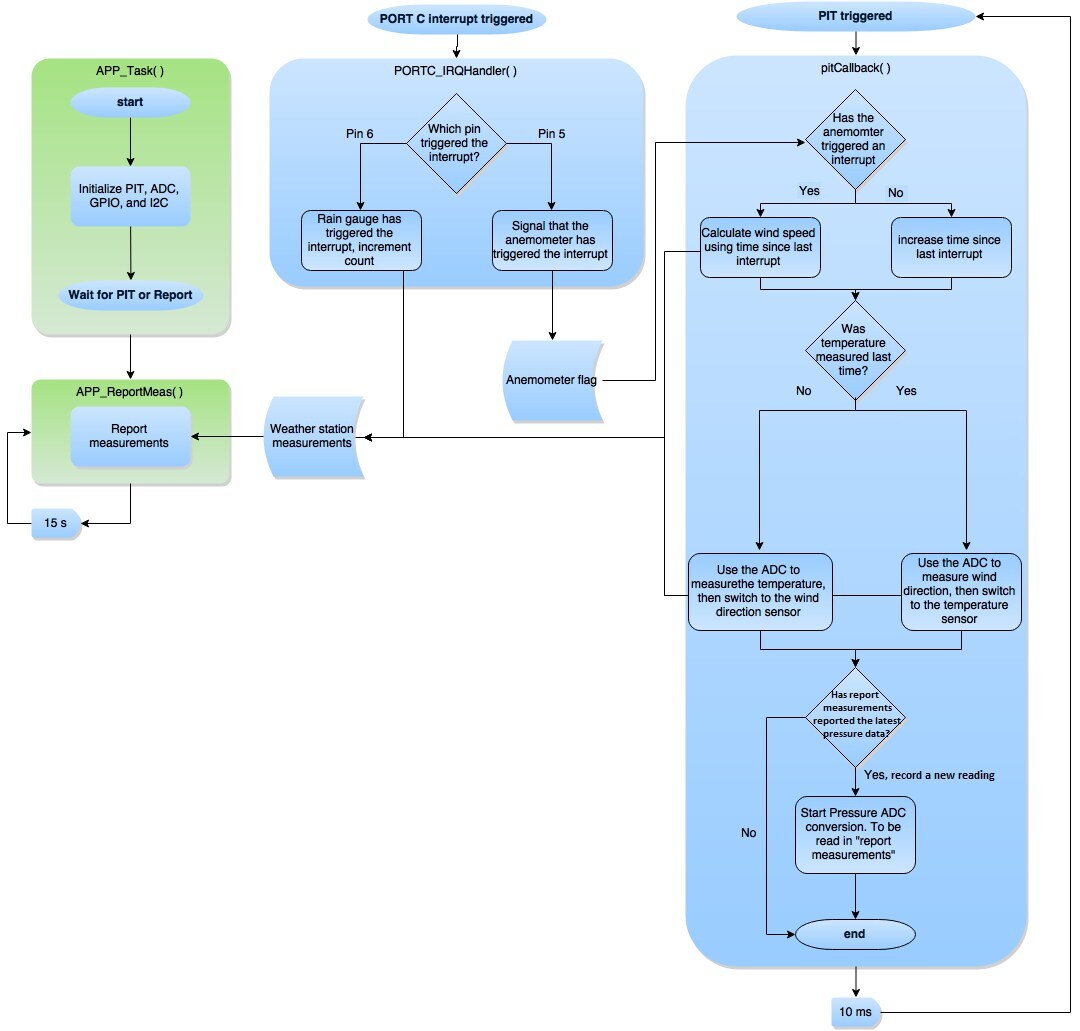

the sensors and getting them to all work together. The resulting

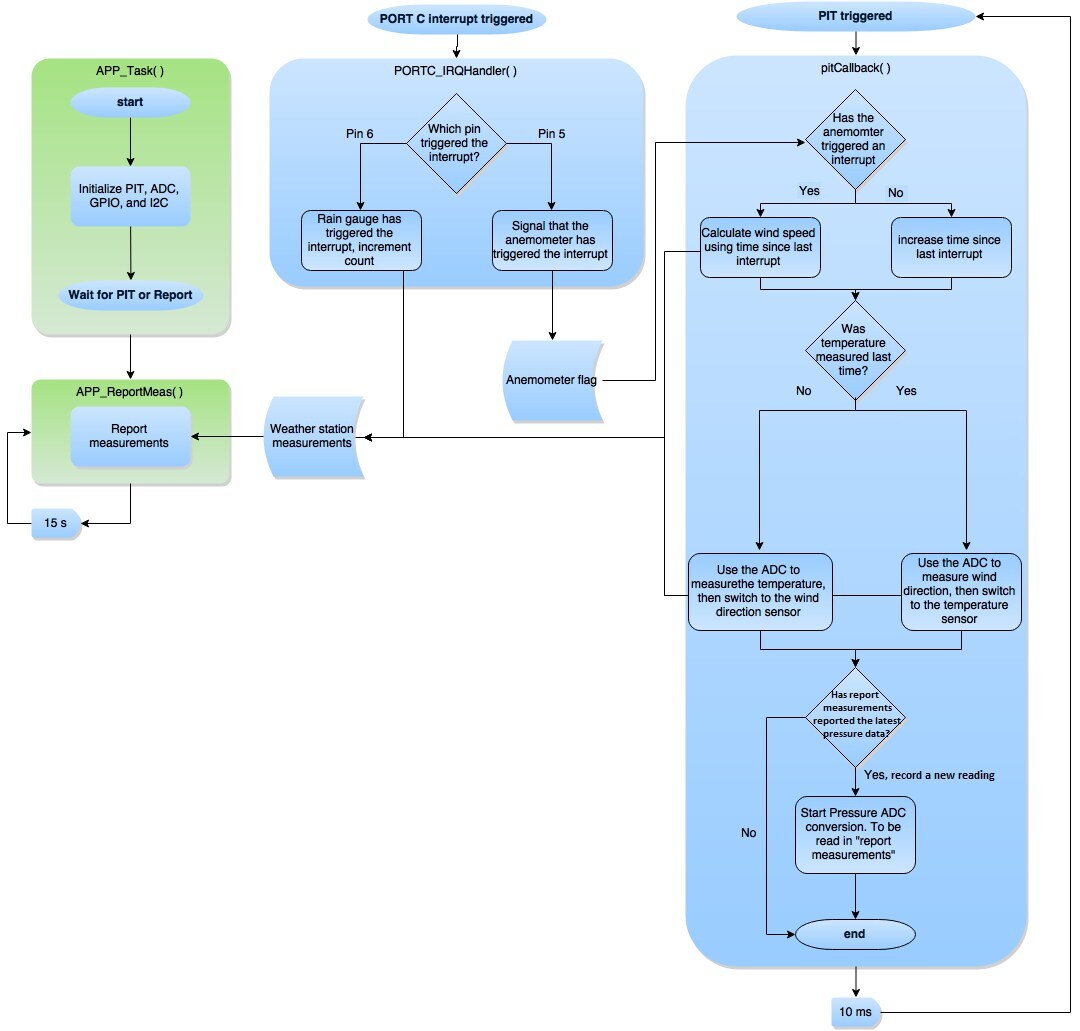

implementation is based on a main sampling loop triggered by a 10ms periodic

interrupt timer, with a callback function that executes the measurement

algorithm for each sensor. The operation and measurement algorithm for each

sensor is briefly described as follows:

Weather station software design

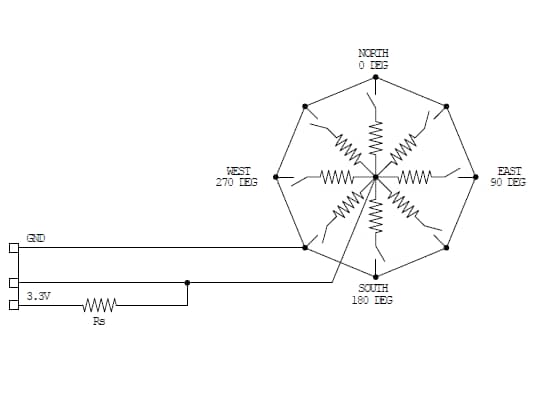

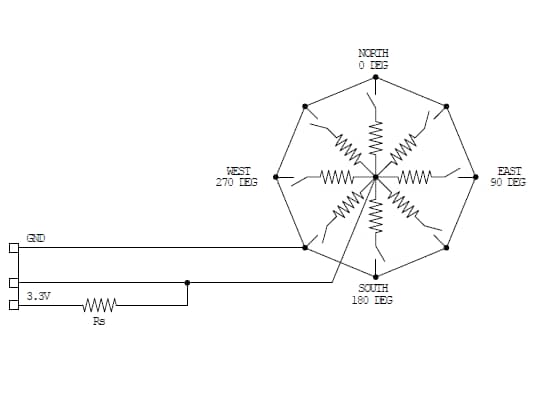

Wind vane

The wind vane sensor is a voltage divider

consisting of a resistor array connected with eight magnetic reed switches. A

magnet on the wind vane closes either one or two adjacent switches depending

on the wind direction. This produces one of 16 different voltage levels

corresponding to 16 discrete compass directions. The voltage is measured on

one of the ADC channels and a lookup table is used to translate each voltage

range to a corresponding wind direction. However, because the voltage levels

do not change monotonically with wind direction we implemented a debounce

algorithm to ensure that voltage transitions are not interpreted as an

incorrect direction.

Wind vane voltage divider circuit

Anemometer

The wind speed measurement uses a cup-type

anemometer with a magnetic reed switch that generates a pulse with each half

rotation. One pulse per second corresponds to a wind speed of 1.492 miles per

hour. In order to provide sufficient accuracy over a wide range of wind

speeds, the measurement algorithm measures the interval between pulses. A GPIO

input channel is configured to trigger an interrupt on the rising edge of each

pulse. The interrupt sets a flag that is checked every 10ms by the main

measurement loop, and a software counter records the number of 10ms intervals

since the previous pulse. If the flag has been set, the wind speed is

calculated from the counter value and the counter is reset; if not the counter

is simply incremented. This solution provides an error of <10% for wind

speeds up to 15 miles per hour and a maximum measurement of 149.2 miles per

hour. A 30 second timeout defaults the measured wind speed to zero for wind

speeds less than 0.05 miles per hour.

Rain gauge

The rain gauge measures rainfall using a self-emptying bucket with a magnetic

reed switch that generates a pulse each time the bucket tips. Each tip of the

bucket indicates 0.011 inches of rainfall. Similar to the anemometer, a GPIO

input channel is configured to trigger an interrupt on the rising edge of each

pulse. A software counter records the number of accumulated pulses and thus

the total rainfall. A debounce function eliminates spurious counts from the

reed switch.

Temperature

The TMP36 analog temperature sensor was selected to measure ambient air

temperature. The sensor is protected from the elements and direct sunlight in

a simple housing made from PVC plumbing parts. The temperature sensor is

powered by 3.3V DC from the TWR-KW24D512 board and produces an analog output

voltage that is linear with temperature. The output voltage is measured on one

of the KW24 ADC channels and translated to temperature using specified

calibration values.

During initial testing we noticed some crosstalk between the temperature

sensor and wind direction sensors, which are both measured using multiplexed

channels on the same ADC. This problem was solved by alternating these

measurements between successive 10ms sampling intervals to allow sufficient

settling time on the ADC input. In addition, we filtered the measured

temperature using a 50 sample moving average to reduce noise.

Barometer

The

MPL115A2 absolute digital pressure sensor uses a MEMs pressure sensor and an

onboard processor to convert the atmospheric pressure measurement to a 16-bit

digital value that is communicated over an I2C interface. The TWRPI-MPL115A2

module is attached to the TWRPI connector on the TWR-KW24D512 board, which is

configured to use the I2C interface on the KW24. The MPL115A2 is sampled

every 10ms by the main measurement loop, and the measured value is filtered

using a 30 sample moving average. An initial setup routine performs

calibration of the barometer.

Thread Communication

Communicating the sensor data over

the IEEE 802.15.4 network using Thread was actually one of the easiest parts

of this project. The Thread stack implements all the required wireless

networking functionality including link configuration and provisioning,

network topology management and security features. All that was needed was to

assemble the measurements into a JSON (JavaScript Object Notation) string,

which is passed to the Thread stack in a single function call.

The weather station is configured as a Thread Router, which means that it can

act as a repeater node in the mesh network as well as a source of sensor data.

For this demo we used a USB-KW24D512 configured as the Thread Border Router.

The USB-KW24D512 communicates with a Utilite IOT Gateway running Proximetry

AirSync agent to send the measurement data to the Proximetry cloud service.

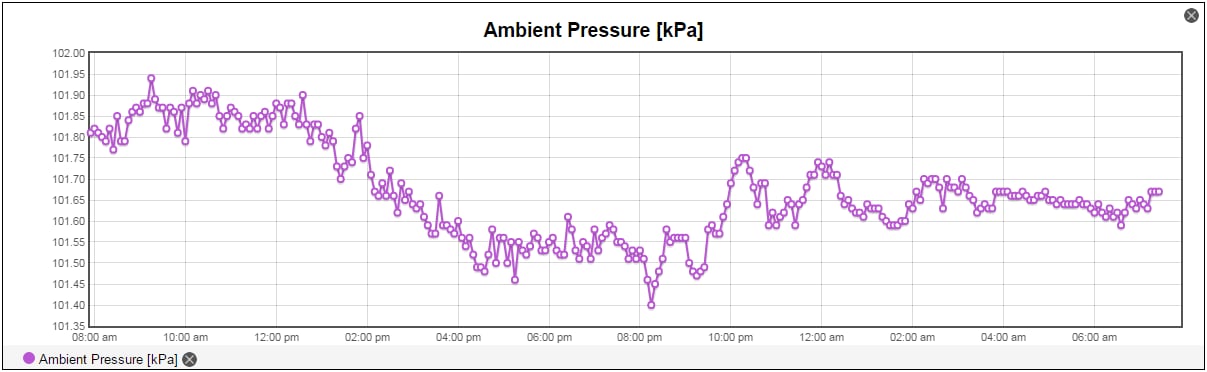

The weather station is configured to transmit data once every 15 seconds,

although this can easily be changed. The data appears in near-real time on the

Proximetry portal, which also provides network status and topology

information.

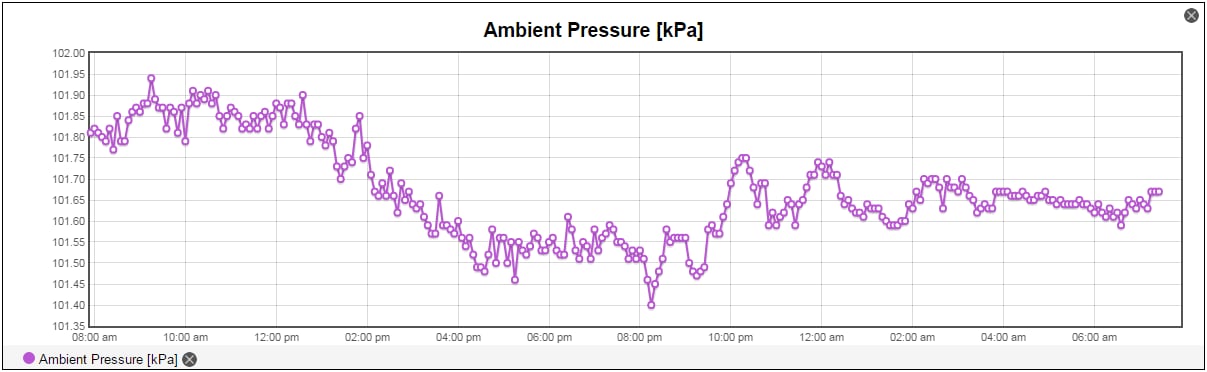

Ambient pressure: Weather station data on the Proximetry portal

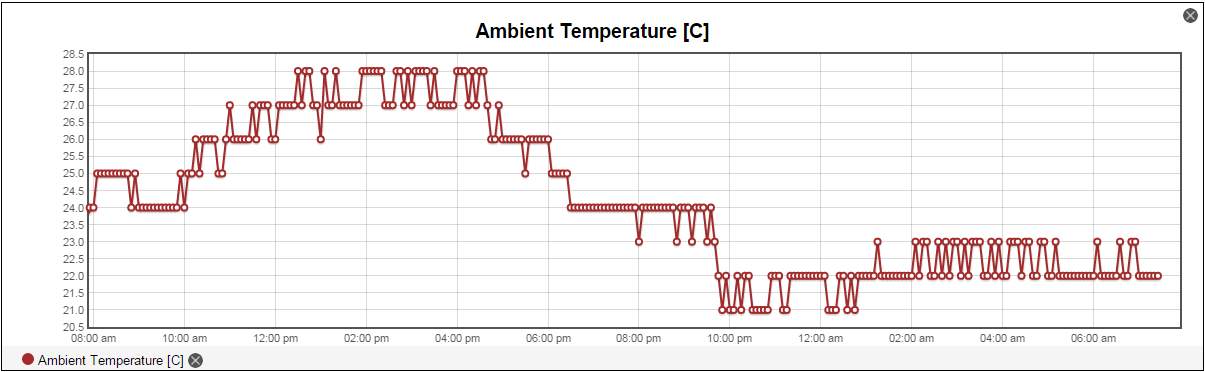

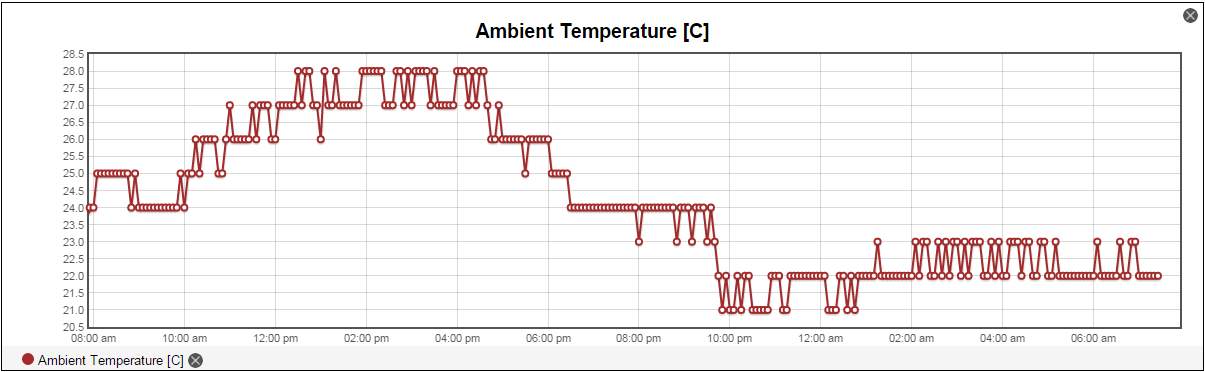

Ambient temperature: Weather station data on the Proximetry portal

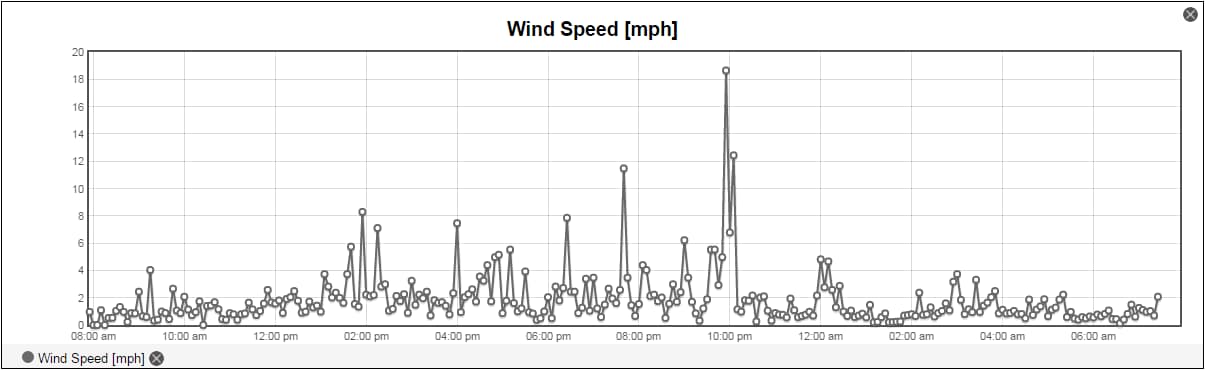

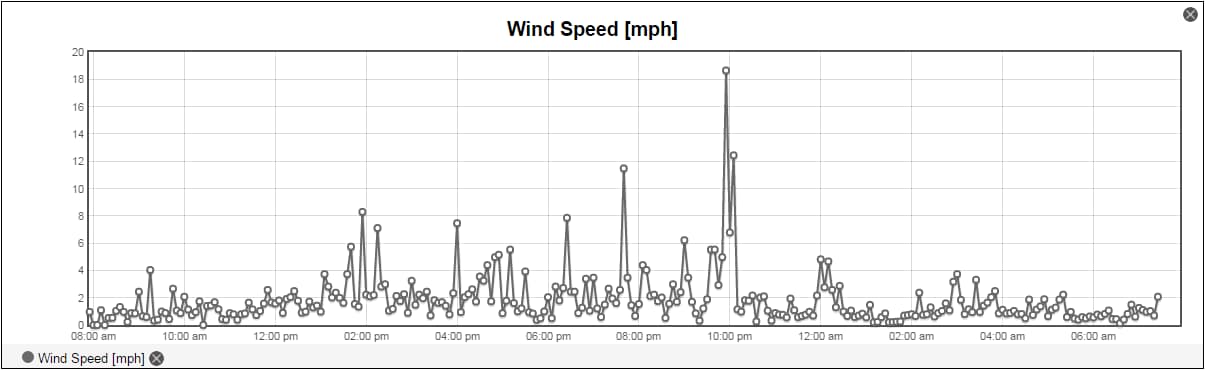

Wind speed: Weather station data on the Proximetry portal

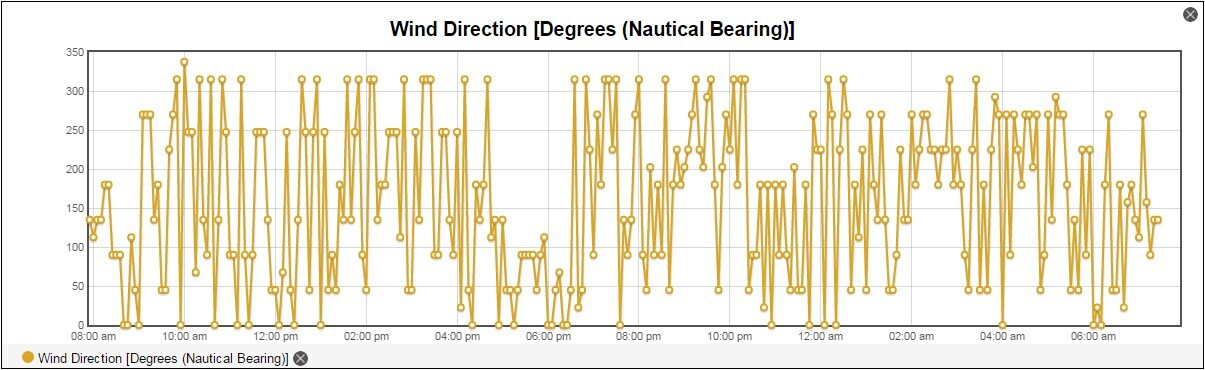

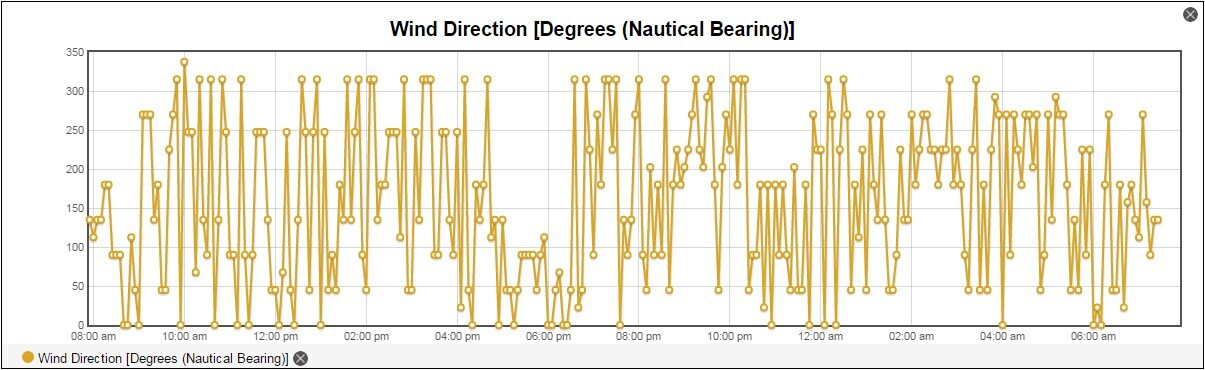

Wind direction: Weather station data on the Proximetry portal

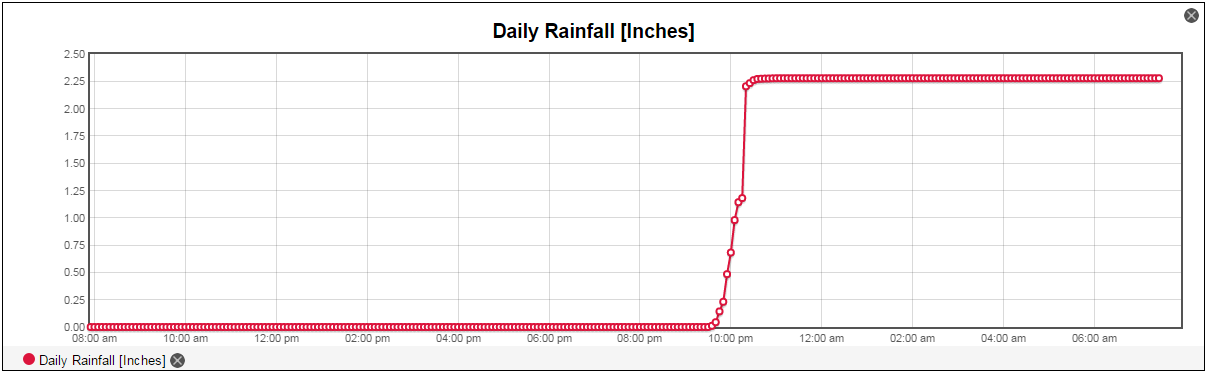

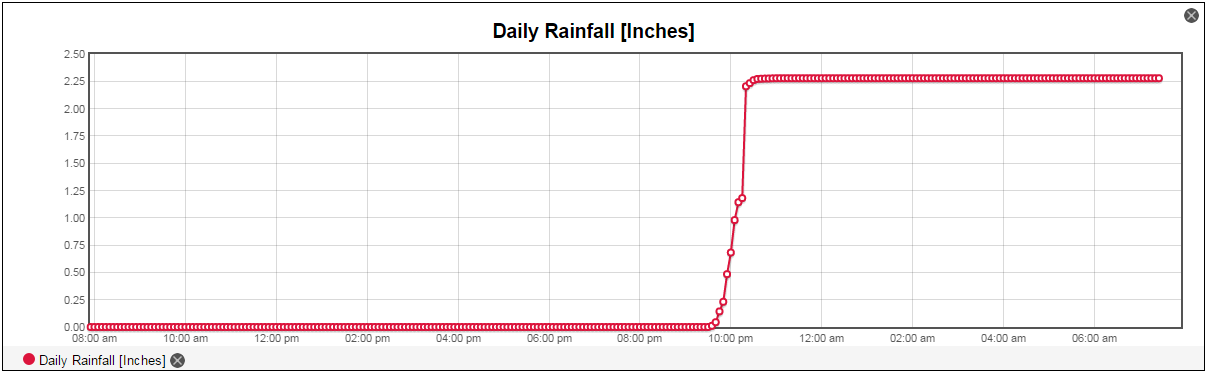

Daily rainfall: Weather station data on the Proximetry portal

The students completed the weather station design, and we have since built

additional demo installations that are being used in customer demos

around the world. In the end, this turned out to be a highly rewarding project

and the students learned a lot – not only about

our microcontroller and Thread networking technologies but also about the

process of specifying, designing, building, coding, testing and documenting. I

can’t wait to see the great new IoT “Thing” they come up

with next!